Electronics Manufacturing

Industry

Achieve your growth aspirations with our transformation process

The FlowPlus™ transformation process

Over 20 UK electronics manufacturers

have transformed their business with our

4-step process

1. DISCOVERY

By starting with a discovery phase, we understand your unique production process and the challenges you face - uncovering areas for improvement and your gap-to-potential.

Gain all the insight in one, concise, step by step assessment report.

01

Lean Maturity Audit

Assess your lean maturity across 25 categories including efficiency, automation, visual management, standards, process control, customer focus, product flow, leadership, culture and more.

02

Performance Analysis

Great processes create great results, Simple but not easy.

We review your current processes to gain an in-depth understanding of existing pain-points, where information sharing and communication breaks down & waste steps that can be eliminated/automated.

03

Gap to potential analysis

Quantify the gap between your current state and desired state, understand what changes are needed to become best-in-class manufacturers.

04

Implementation roadmap

Convert improvement actions into projects, and produce a bespoke improvement roadmap aligned with your company strategy.

2. ASSESSMENT

The Assessment phase investigates the unique solutions required to close your gap-to-potential and become a best-in-class manufacturer. Creating a bespoke implementation roadmap aligned with your strategic aims, we provide you with a practical step by step approach needed to get tangible results fast.

05

Customer Feedback Analysis

Using AI and advanced machine learning techniques, we will identify what your customers care most about and innovative ways of exceeding their expectations.

06

Value Stream Mapping

Painting a clear picture of your manufacturing system, you will start to see the waste and improvement opportunities that have been hidden all this time.

07

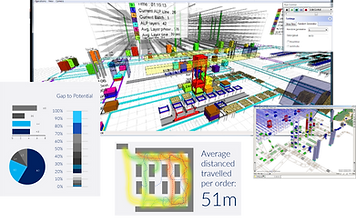

Motion tracking

Quantify the waste of motion & transport with the latest technology. Find optimised layouts and floorplans by tracking products, people & forklifts. Increasing productivity, minimising H&S risks and improving communication.

08

Flow Analysis

There is often huge untapped potential when improving the flow of your system. Understand how to balance work and minimise lead time with our flow analysis tool.

3. IMPLEMENTATION

Implementation is what we pride ourselves on. We don't write reports and leave the hard part to you...We roll up our sleeves, get on the shopfloor and make the changes needed.

Working with the operators that know the processes best, we conduct workshops as one-team, until the target is achieved.

The solutions we implement are tailored to each client and the unique challenges in their assessment. Examples range from re-designing and transforming a factory layout to maximise flow and improve efficiency, through to implementing machine vision systems to automate quality inspection.

40% reduction in Lead Time

30% improvement in productivity

35% increase in quality yeild

55% decrease in machine downtime

4. TRAINING

We offer both in-person & online training. Both training courses are deliberately different to other training providers in one main way, it's practical & hands-on.

Our online training course has global recognition and has a review rating of 4.8/5 from over 7,500 active students.

Like the in-person training, the online courses provide you with the practical ability to apply the lean tools.

We have 5 different courses varying in complexity/commitment.

7500+

No of students we have trained globally

Topics covered in the training

-

What is Lean?

-

Lean in the Electronics Industry

-

Best-in-class electronics case studies

-

Introduction to Six Sigma

-

Identifying and Eliminating Waste

-

History of Lean

-

Kaizen (Yellow)

-

Change management & Paradigms

-

Flow, Batch Sizes, Push vs Pull & Takt

-

Visual Management

-

Line Layout & design

-

Supermarkets

-

Hoshin Kanri

-

Spaghetti Diagrams

-

Value Stream Mapping (VSM)

-

Overall Equipment Effectiveness (OEE)

-

Standards & Standard Work

-

Total Productive Maintenance (TPM)

-

Quick Changeovers (SMED)

-

5s - Productive Workspaces

-

Collaborative Problem Solving, A3, 5Whys, Fishbone, Root Cause Analysis (RCA)

-

The DMAIC Process

-

Advanced DMAIC process

-

Taguchi Loss Function

-

Statistical Process Control

-

Kano Model

-

Quality Function Deployment

-

Training within Industry

-

Logistics trains

-

Voice of the customer

-

Process Mapping

-

Standard work

-

Work Balancing

-

Heijunka

CASE STUDIES

A selection of success stories.

Electronics Manufacturer

Introduced a Kanban replenishment system

Reduced product lead time by ~63% and reduced annual stock holding cost by over £1million.

UK Automotive

Increased OEE by 17%

Implemented a total productive maintanence regime throughout the plant to reduce machine downtime and boost OEE by 17%.

UK Electonics Manufacturer

Implemented and populated a digital standardised work system

Reduce rework by 31%

Reduced on-boarding training time by 54%.

UK Electronics Manufacturer

Increased labour productivity by 35%

Introduced a kitting process to deliver components to workstations and reduce operator motion.

TESTIMONIALS

FlowPlus helped us unlock our potential and as a result of their input we have delivered significant business improvement.

Caroline Grant -

Production Director, Biscuiteers

The FlowPlus training has been a key part of our Lean transformation. We put all of our senior operators through the green belt training and saw significant improvements from the projects they completed as part of the training.

Arif Ali -

Head of CI

FlowPlus assisted us with implementing a TPM program and their team worked tirelessly not just to get immediate results but to spent a lot of time sharing knowledge with our maintanence department allowing us to continue developing our TPM ourselves.

Lukasz Krawczyk -

Head of Engineering